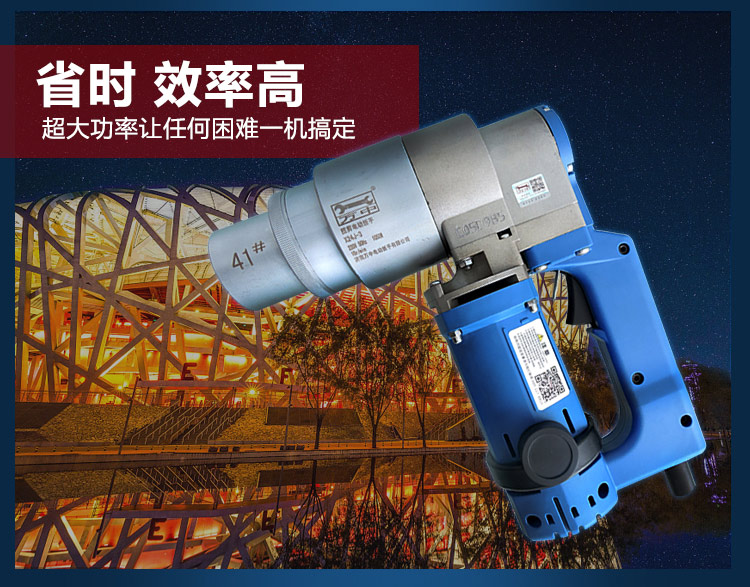

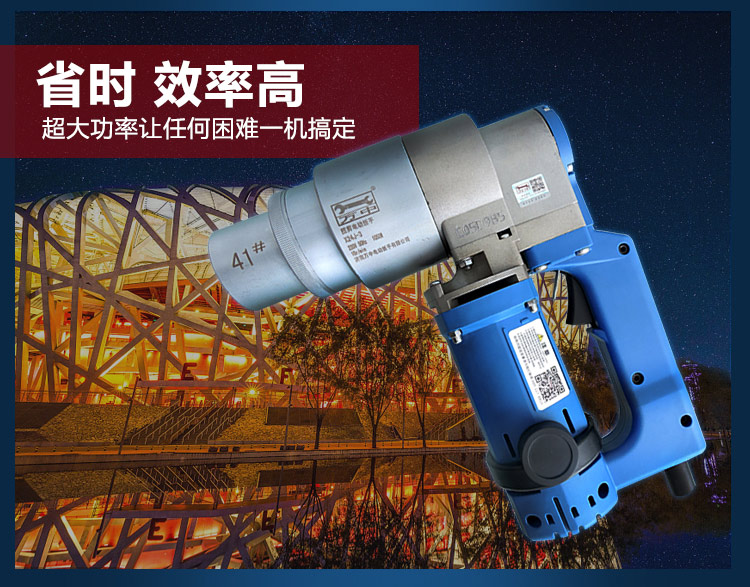

扭剪型螺栓必威西汉姆联官网g1线路具有自动控制扭矩功能是装配螺纹件及螺栓的机械化施工工具。本款扭剪型螺栓必威西汉姆联官网g1线路应用于栓焊结构桥梁的架设,厂房、塔架及化工、冶、发电设备的安装。此款扭剪型螺栓必威西汉姆联官网g1线路还应用于大型机械、起重设备和车辆装配作业以及对螺纹紧固件的扭矩及轴向拉力有严格要求的场合。

Torsional shear bolt electric wrench with automatic torque control function is a mechanized construction tool for assembling threaded parts and bolts. This torsional shear bolt electric wrench is used for the erection of bolted and welded bridges, and the installation of plants, towers and chemical, metallurgical and power generation equipment. This type of electric wrench for torsional shear bolts is also used in the assembly of large machinery, lifting equipment and vehicles, as well as the occasions where there are strict requirements on the torque and axial tension of threaded fasteners.

扭剪型螺栓必威西汉姆联官网g1线路扭矩的选择与调节

Selection and Adjustment of Torque of Electric Wrench for Torsion Shear Bolts

1、用户可在1000-2500Nm的范围内任意选择相应规格的扭剪型螺栓必威西汉姆联官网g1线路。

1. The user can choose the electric wrench with the corresponding specifications for the torsional shear type bolts within the range of 1000-2500Nm.

2、控制仪面板上有“扭矩调解旋钮”。刻有0-10个刻度值。细调旋钮的作用是在粗调两档之间进行调节补偿,以扭矩控制精度。

2. There is a "torque adjustment knob" on the control instrument panel. It is engraved with 0-10 scale values. The fine adjustment knob is used to adjust and compensate between the two coarse adjustment gears, so as to control the accuracy with torque.

3、调节方法:国产品出厂时带有扭矩测试数据卡片,供用户标定时参考,用户可根据所需扭矩选择某一刻度值,按拧紧螺栓的操作方法,拧紧螺栓,用测力扳手或其它测力仪器测出螺栓的实际扭矩值,若扭矩相差较小,可用细调加以补偿,若相差较大,可将粗调向上或向下调一档,反复几次即可获得所需扭矩值。

3. Adjustment method: Chinese products are provided with torque test data cards when leaving the factory for reference when users calibrate. Users can select a scale value according to the required torque, tighten the bolts according to the operation method of tightening the bolts, and measure the actual torque value of the bolts with a force measuring wrench or other force measuring instruments. If the torque difference is small, fine adjustment can be used to compensate. If the difference is large, coarse adjustment can be made up or down one gear, Repeat several times to obtain the required torque value.

扭剪型螺栓必威西汉姆联官网g1线路螺栓的拧紧操作

Torsional shear type bolt Tightening operation of electric wrench bolt

1、装上反力支架,并紧固螺钉。开动主机,使方头销孔与反力支架孔相对应,然后装入扳手套筒,插上销钉,并用橡胶圈固定。

1. Install the reaction support and tighten the screws. Start the host machine to make the square head pin hole correspond to the counter force support hole, then install the wrench socket, insert the pin, and fix it with a rubber ring.

2、将控制仪的扭矩旋钮调到所需扭矩值,将主机正反开关拨到正转位置,把扳手套筒套在螺纹连接件的六方上。

2. Adjust the torque knob of the controller to the required torque value, turn the positive and negative switches of the host to the forward rotation position, and put the wrench socket on the hexagon of the threaded connector.

3、按下电源开关,扳手启动。当反力支架力臂靠牢支架时(支点可以是邻近的一只螺栓或其他可作支点的位置)螺栓开始拧紧。当螺栓扭矩达到预定扭矩时,扳手自动停止,紧固完成,松开电源开关,进行下一只螺栓的拧紧工作。

3. Press the power switch and the wrench starts. When the reaction support arm is firmly against the support (the fulcrum can be an adjacent bolt or other positions that can be used as fulcrums), the bolt starts to tighten. When the bolt torque reaches the predetermined torque, the wrench will stop automatically. After tightening, loosen the power switch and tighten the next bolt.

4、扳手自动停止后,靠反力支架的弹性形变力,使支架力臂自动脱离支点,取下扳手。如力臂不能脱离支点时,可拨动正反开关,点动电源开关扳手即可取下。

4. After the wrench stops automatically, the support arm will automatically disengage from the fulcrum by the elastic deformation force of the reaction support, and the wrench will be removed. If the lever arm cannot be separated from the fulcrum, the positive and negative switches can be toggled, and the power switch wrench can be inched to remove it.