高强度螺栓所用材料的强度为普通螺栓的4~5倍,一般常用的性能等级为8.8级和10.9级。8.8级采用优质碳素钢35号钢或45号钢;10.9级采用合金结构钢20MnTiB、40B、35VB。高强度螺栓有大六角头螺栓和扭剪型两类。钢结构规范规定,高强度螺栓的材料应符合现行标准的规定。

The strength of the materials used for high strength bolts is 4 ~ 5 times that of ordinary bolts, and the commonly used performance grades are 8.8 and 10.9. Grade 8.8 adopts high-quality carbon steel 35 or 45; grade 10.9 adopts alloy structural steel 20MnTiB, 40b and 35VB. There are two types of high strength bolts: large hexagon head bolts and torsion shear bolts. According to the specification of steel structure, the material of high strength bolt should conform to the current standard.

高强度螺栓的预拉力由材料的屈服度和螺栓的有效面积并考虑一定摩擦系数确定。高强度螺栓的预拉力是通过施工时紧固螺帽建立的,紧固(拧紧)螺帽的方法有如下几种:

The pre tension of high strength bolt is determined by the yield of material, the effective area of bolt and the friction coefficient. The pretension of high-strength bolts is established by tightening nuts during construction. There are several methods for tightening (tightening) nuts:

(一)扭矩法

(1) Torque method

根据扭矩M与预拉力成正比的关系,先用普通扳手将螺帽初步拧紧,然后采用可显示扭矩值的专用扳手拧至规定的扭矩值。

According to the proportional relationship between the torque M and the pre tension, the nut is initially tightened with an ordinary wrench, and then the nut is screwed to the specified torque value with a special wrench that can display the torque value.

(二)转角法

(2) Corner method

根据板层间紧密接触后,螺母的旋转角度与螺栓的预拉力成正比关系确定的一种方法。

According to the fact that the rotation angle of the nut is proportional to the pretension of the bolt after the close contact between the plates is a method.

紧固时,先用短扳手将螺帽拧至不转动的位置,然后再用长扳手将螺帽拧至规定位置,以达到预拉力。

When tightening, first use a short wrench to screw the nut to the position that does not rotate, and then use a long wrench to screw the nut to the specified position to achieve the pre tension.

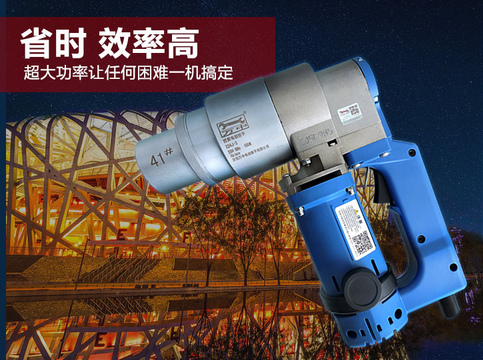

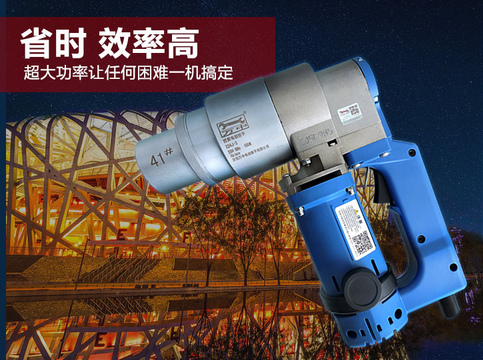

(三)拧断螺栓尾部

(3) Screw off the bolt tail

用于扭剪型高强度螺栓,此螺栓有一特制的尾部。紧固时,用专用扳手套住螺栓和螺栓尾部,一个套筒正转,另一个套筒反转,在螺帽拧紧到一定程度时,螺栓尾部拧断。由于螺栓尾部的槽口深度是按拧断扭矩和预紧拉力之间的关系确定的,所以拧断时就达到相应的预拉力值。

For torsion shear type high strength bolt, this bolt has a special tail. When tightening, use a special wrench to hold the bolt and the bolt tail, one sleeve rotates forward, the other sleeve reverses, and when the nut is tightened to a certain extent, the bolt tail will be broken. Because the notch depth of the bolt tail is determined by the relationship between the torque and the pre tightening force, the corresponding pre tension value is reached when the bolt is broken.

高强度螺栓连接中,摩擦系数的大小对承载能力的影响很大。试验表明,摩擦系数与构件的材质、接触面的粗糙度、反向力的大小都有直接关系,其中主要是接触面的形式和构件的材质。为了增大接触面的摩擦系数,施工时应将连接范围内构件接触面进行处理,处理的方法有喷砂、用钢丝刷清理等。设计中,应根据工程情况,尽量采用摩擦系数较大的处理方法,并在施工图上清楚注明。

In the high strength bolt connection, the friction coefficient has a great influence on the bearing capacity. The test results show that the friction coefficient is directly related to the material of the component, the roughness of the contact surface and the size of the reverse force, among which the form of the contact surface and the material of the component are the main factors. In order to increase the friction coefficient of the contact surface, the contact surface of the components within the connection range should be treated during construction. The treatment methods include sand blasting, wire brush cleaning, etc. In the design, the treatment method with larger friction coefficient should be adopted as far as possible according to the engineering situation, and it should be clearly indicated on the construction drawing.

除上述处理方式外,还有一种用手提式电动砂轮打磨接触面的处理方法,打磨方向要与受力方向垂直,其抗滑系数相当于喷砂处理。

In addition to the above treatment, there is also a treatment method of grinding contact surface with portable electric grinding wheel. The grinding direction should be vertical to the force direction, and its anti sliding coefficient is equivalent to sandblasting treatment.