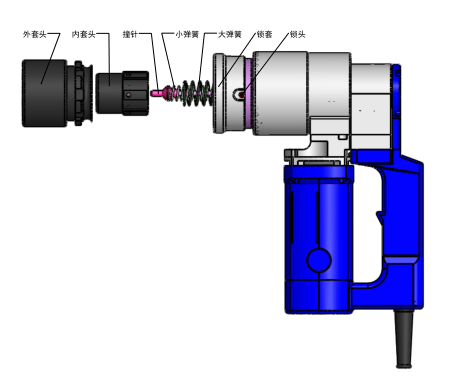

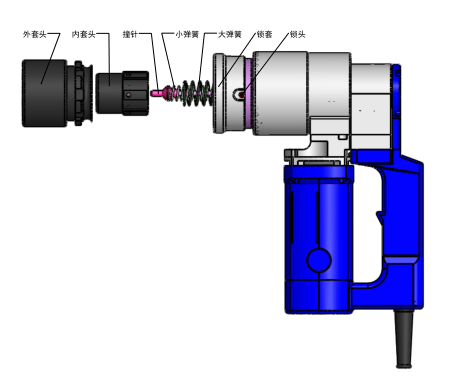

1.把锁头按入机器内(正面.背面各一个)

1. Press the lock head into the machine (one on the front and one on the back)

2.把锁套滑向机体一侧滑动至底部,套头会自动弹出

2. Slide the lock sleeve to one side of the machine body to the bottom, and the sleeve will pop up automatically

3.把撞针、大弹簧、小弹簧分别按图示装好

3. Install the striker, large spring and small spring as shown in the figure

4.把内套头与外套头分别与机器上的卡槽相对应并且卡入卡槽

4. Align the inner sleeve head and outer sleeve head with the clamping groove on the machine and clip them into the clamping groove

5.向远离机器方向推动锁套至锁头卡入锁套的小孔使锁套固定

5. Push the lock sleeve away from the machine until the lock head snaps into the small hole of the lock sleeve to fix the lock sleeve

6.套头更换完成可以使用

6. The socket can be used after replacement

高强度扭剪螺栓的预紧力-钢结构的强度螺栓是通过拧紧螺母来实现的。通常使用扭力法、角度法或扭断螺栓尾部的方法来控制预紧力。目前有专用扳手显示扭力.通过测得的扭矩与螺栓张力的关系,施加扭矩达到必要的过张力值。

Preload of high-strength torsion shear bolt - the strength bolt of steel structure is realized by tightening the nut. Torque method, angle method or the method of breaking the bolt tail are usually used to control the preload. At present, there are special wrenches to show torque Through the relationship between the measured torque and bolt tension, the applied torque reaches the necessary over tension value.

转角法转角法分为两步,一是初始拧紧,另一个是终拧紧。简单的说,初拧一般是工人用普通扳手使被连接的部件紧密贴合,而终拧紧是以初始拧紧位置为起点,终拧紧角度为根据螺栓直径和层压板的厚度确定。

Angle method angle method is divided into two steps, one is initial tightening, the other is final tightening. In short, the initial tightening is generally that workers use an ordinary wrench to make the connected parts closely fit, while the final tightening is based on the initial tightening position as the starting point, and the final tightening angle is determined according to the bolt diameter and the thickness of the laminate.

用扳手转动螺母,当拧到预定角度值时,螺栓的拉力可以达到所需的预紧值。为防止高强度螺栓受外界环境影响而改变扭矩系数,一般初、终拧紧应在同内完成。高强度扭剪螺栓的受力特性与一般高强螺栓的受力特性相同,只是施加预紧力的方法是通过破坏螺栓头切口的横截面来控制预紧力的值。

Turn the nut with a wrench. When it is screwed to the predetermined angle value, the tension of the bolt can reach the required pre tightening value. In order to prevent the high-strength bolt from changing the torque coefficient due to the influence of the external environment, the initial and final tightening should be completed in the same day. The stress characteristics of high-strength torsional shear bolts are the same as those of general high-strength bolts, but the method of applying preload is to control the value of preload by destroying the cross section of the bolt head notch.

摩擦式高强度扭剪螺栓连接完全依靠被连接部件之间的摩擦阻力,摩擦阻力不仅是螺栓的预紧力,还取决于由以下因素决定的防滑摩擦面连接元件材料及其接触面的表面处理。看完相信大家已经基本明白高强度螺栓应该用在什么地方以及正确的操作和拧紧了。

Friction type high-strength torsional shear bolt connection completely depends on the friction resistance between the connected parts. The friction resistance is not only the preload of the bolt, but also depends on the surface treatment of the connecting element material and its contact surface determined by the following factors. After reading, I believe you have basically understood where high-strength bolts should be used and the correct operation and tightening.

The above is about the introduction of torsional shear electric wrench. I hope it will be helpful to you If you have any questions, please contact us We will provide you with professional service